Screw compressor technology.

- The design and mechanical machining of all components of Fini rotary screw compressors is carried out in our factories in Italy with the help of computer-aided modelling and design tools.

- Mechanical processing is carried out using state-of-the-art numerical control machines.

- All components undergo rigorous quality control to ensure perfect compliance with specifications.

- Assembly of screw units and complete compressors is carried out in our Italian factory in Zola Predosa, in the province of Bologna.

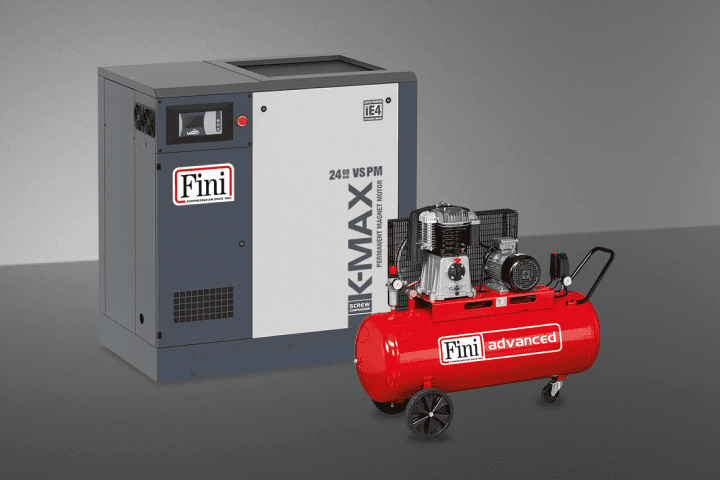

Single-stage lubricated screw compressors

With a line of lubricated, single-stage, direct and belt transmission screw machines ranging in power from 2.2 to 90 kW, and an unrivalled variety and completeness of equipment, Fini is able to satisfy any company’s compressed air needs, both in terms of generation and treatment accessories.

Double-stage lubricated screw compressors

For the most demanding applications, where the powers at stake require maximum efficiency and reliability, Fini offers an important and complete line of double-stage lubricated screw compressors, from 75 up to 315 kW. Solidity, performance and efficiency without compromise.