How to choose a compressor?

Understanding the requirements

FINI boasts one of the most comprehensive compressor ranges on the market. But before you choose which one is right for you, you need to ask yourself a few simple questions:

- Which of my activities require the use of compressed air?

- Which type of compressor is most suitable?

- What is the air flow rate that allows me to carry out my activities correctly?

- Is the volume of compressed air required by the application: constant, variable, or intermittent (minimum to maximum)?

- What is the maximum pressure required?

- With reference to ISO 8573-1:2010 (purity classes for dust, water and oil), does the quality of the compressed air matter for my application?

- How important is quiet operation?

- Does it need to have a tank? What capacity must it have?

Identify the technology: screw, piston or scroll (oil-free)?

Piston compressors are perfect for small to medium air volumes and high intermittency, thus for craft, professional and DIY applications.

Rotary screw compressors, on the other hand, are suitable for larger air volumes and offer excellent coverage of both variable and constant compressed air requirements with very high efficiency, thus for industrial and professional applications.

Scroll compressors are industrial compressors specifically for all applications requiring completely oil-free operation, such as the food industry.

Start by defining the pressure required for the specific application: each tool and device lists the minimum pressure required for proper operation and compressed air requirements.

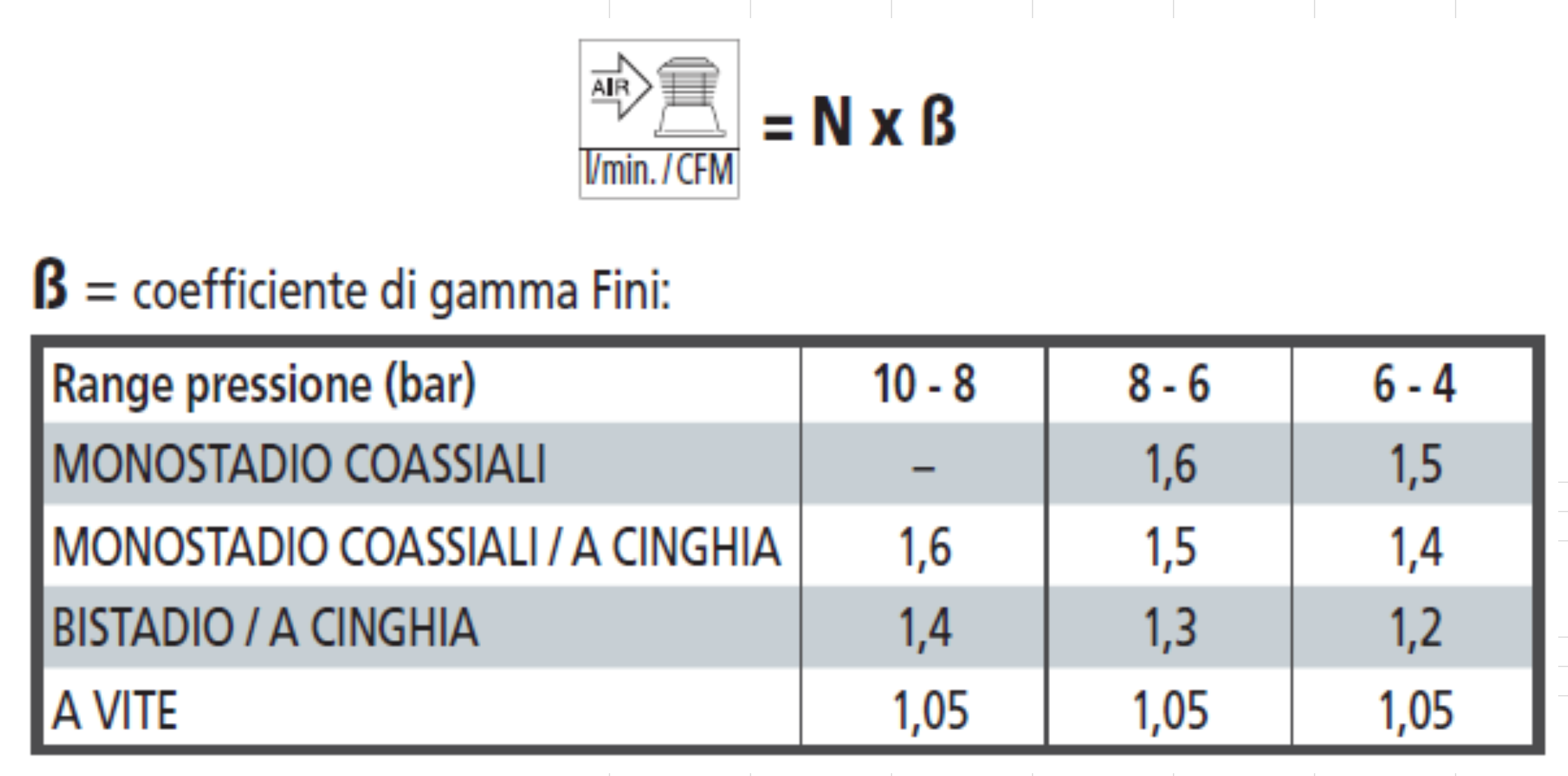

Compressed air consumption can be calculated in different ways: if you already have a compressor and a tank, we recommend the following procedure.

Just count how many seconds it takes the pressure to drop by a certain value in the tank (with the compressor NOT running) and apply the formula:

N = V x dP x 60 / t

First, this identifies the pressure required for the desired application, which may vary depending on the type of compressor and the intended uses. For example, if you wish to inflate tyres or use pneumatic tools, you must check what the recommended operating pressure is for such devices.

Lubricated or oil-free?

The choice depends on the specific requirements of the application and on efficiency and compressed air quality considerations.

The oil-free compressor is ideal for clean, contaminant-free air, but also for applications where lubrication could compromise the function of components and in the food industry.

On the other hand, the compressor with oil is recommended in applications with a high workload. In these cases, the oil serves to reduce wear on moving parts, improve efficiency and dissipate heat generated during operation.

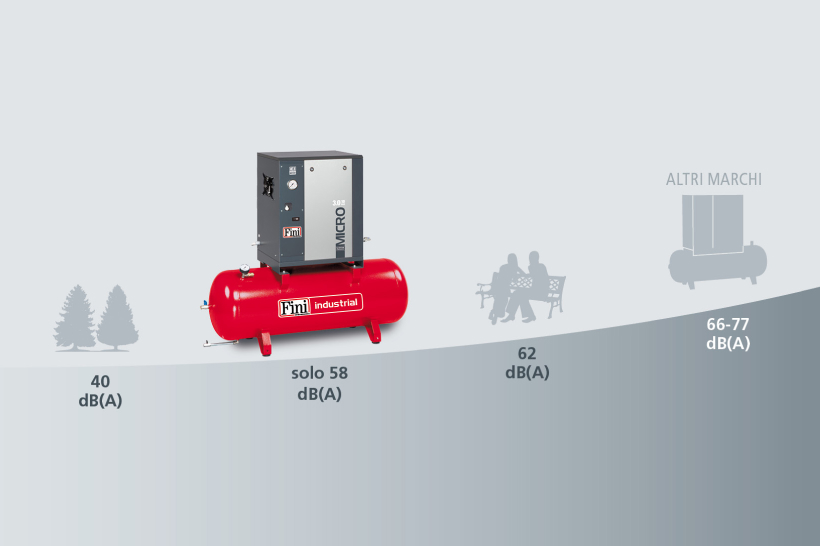

Will it be quiet enough?

All Fini compressors are designed with the utmost attention to noise reduction.

In particular, noise reduction in the silenced, screw and scroll ranges is achieved by enclosing the machine in a soundproof cabinet with special sound-absorbing panels, taking care of ventilation. These compressors distinguish themselves on the market by having the lowest noise level in their class.

Do I need a bigger tank?

The capacity of the tank must be assessed according to your needs, taking into account the capacity of the compressor. Generally speaking, a volume in litres equal to at least one third of the compressor’s air flow is considered (e.g.: flow rate 1500 l/min – tank volume 500 l).

Find your new compressor

Piston

Perfect for small to medium air flow rates with high intermittency, e.g. inflating, blowing, nailing, airbrushing, washing.

Screw

Suitable for higher flow rates, provide an excellent coverage of compressed air demand, both variable and constant needs, as well as extremely high efficiency levels.

Scroll

The SCROLL rotary system is a proven technology developed to compress air in the absolute absence of oil.